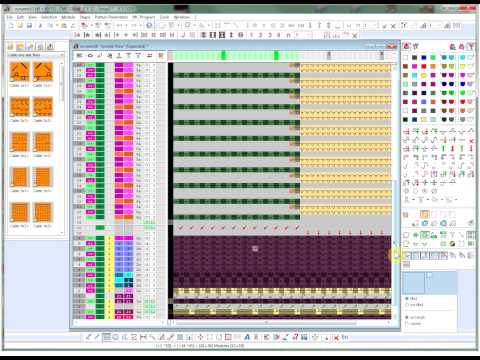

A big hit: All editing steps carried out can be saved and reloaded anytime, forwards and backwards. After that, the fabric and technical views are available to you. With this method, module expansion and the separation of the intarsia rows take place in a concluding step. Therefore, you can first concentrate solely on your design and finish it more quickly, even with the most complicated patterns. Also, at this stage you don’t have to worry about whether the modules contained in the pattern fit together. No complex calculation processes take place in the background during this. Starting programming in the Design Mode has a special advantage: You only work with the compact symbol view. There are two ways to begin working out a pattern program: In the new Design Mode or in the familiar Technical Mode. WE GO A STEP FURTHER SO YOU CAN MAKE PROGRESS FASTER.

The M1plus® using picture import and export as well as a special interface for shapes offers you a high degree of freedom regarding design, fabric simulation and presentation. The options for linking ENEAS Informatica software to Another highlight is our exclusive coopera cooperation tion with ENEAS Informatica in flat knitting. And fast creation of different sizes for production is no problem with the M1plus®.

Naturally, the program still supports you with numerous built-in automatic functions, but you can also work

In addition, we have reengineered the menu guidance system, made operation even easier and implemented new functions. But now with the new Design Mode and new Arrangement Technology, we have made it possible to complete a pattern even faster. That also means that patterns from the preceding versio versionn are absolutely compatible with the new version. ®įirst, the most important news: With M1plus you can continue working as usual. The result is an even more flexible pattern software with even more influencing options for the programmer: M1plus ®. We have also taken many suggestions from our customers and the market demand into account in the continuing development of our established pattern software. For example, this is how the world’s first mass-produced computer-controlled flat knitting machines (1975) and the CMS Generation (1987) were developed. This is especially due to the fact that we have always reacted to the needs of our customers. Stoll has been a synonym for flat knitting machines of the highest quality for almost 135 years. USER-FRIENDLY INDIVIDUAL SIMPLE FLEXIBLE TIME-SAVING INTELLIGENT USER-FRIENDLY INDIVIDUAL SIMPLE FLEXIBLE TIME-SAVING INTELLIGENT Training is available for the programming software M1plus, its successor software k.innovation Create Plus, and the design software k.innovation Create Design.USER-FRIENDLY INDIVIDUAL SIMPLE FLEXIBLE TIME-SAVING INTELLIGENT PATTERN PA TTERN SOFTWARE M M1PLUS 1PLUS® The TexLab serves as a training facility for machine operation, and for Stoll design and programming software. The presence of some yarn suppliers and other industry partners will complete the event.įor product development and the transfer of know-how, the TexLab offers a quite complete range of Stoll flat knitting machines including the ADF machines with a working width of 50" to 84" for technical textiles and fashion. Highlights at the event will include various Stoll machines in action, with a few models that were not shown before, seminars and workshops to introduce new design and programming software, and many inspiring knitted products for fashion and for technical textile markets. Business partners can get to know the fully equipped TexLab, with the latest Stoll machines, other equipment to develop knitted products and multiple collaboration and training areas. The first Stoll Days for customers and other interested parties will take place from June 7-10, 2022 in the new TexLab in Greensboro. Investments were also made here in a state-of-the-art development and visitor center, to be used for demonstration of all technologies of the Karl Mayer Group, Obertshausen/Germany, and for Stoll knit product prototype development and for training. In 2020, the Karl Mayer Group acquired Stoll, and in 2021 US operations of the flat knitting machine company were relocated from New York City, NY/USA, to the location of Karl Mayer North America in Greensboro, NC/USA.

0 kommentar(er)

0 kommentar(er)